for the development of next-generation forging products that will be applied to future technologies in our major business areas,

and continue to develop. About the Institute, research areas, research facilities, research achievements

-

01

Free forging,

Ring mill forging· Forging method development/improvement

· mold development

· heat treatment process

optimisation materials and heat treatment research

-

02

Research &

Development· Materials and heat treatment research

· Process design and analysis CAE -

03

Technical support

· R&D DB establishment,

· Customer response technical support -

04

Foreign technical work

· Planning and carrying out national (government) research projects

· Intellectual property (patent) application/registration management

· Establishment of industry/university/research network

competitive products to the fast-growing free forging market for ships, plants and wind power generation.

-

Steel material

Optimal alloy design study

-

Forging process control

Research on the optimal forging process through CAE

-

Heat treatment furnace

Optimal microstructure control study according to alloy

-

Analysis evaluation

Material properties analysis

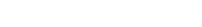

Siemens NX, SolidWorks

Labview

Deform 2D/3D

Dilatometer

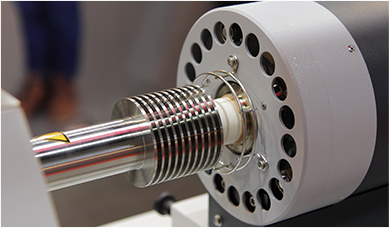

Optical microscope(OM)

Scanning electron microscope(SEM)

reliability evaluation and analysis technology.

High-carbon forged work roll for hot rolling with excellent high-temperature abrasion resistance and mechanical strength, and manufacturing method thereof

(No. 10-1286121, registered in 2013)

A study on the development of cast and forged work roll technology for metal lining machine

2010-2013