Production process

Seohan ENP has the best technology, including high quality large component manufacturing using ingot,

specialised large component manufacturing using Slab, and mold technology, and is committed to developing

new forging technologies.

specialised large component manufacturing using Slab, and mold technology, and is committed to developing

new forging technologies.

Process of selecting and inputting the optimal material (Ingot, Slab, Bloom, etc.) suitable for customer needs

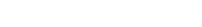

Process of heating the material to an appropriate temperature for the properties of the material grade and forging

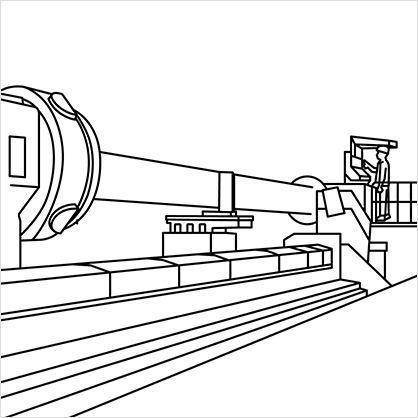

Process of molding the heated material into a shape and size suitable for each product using a press and various molds

Process of delivering the forged material in order to produce it in a shape similar to the final product according to the product shape

Process of heating and cooling the material that has finished forging molding to ensure the mechanical properties are suitable for the product and material properties

Process of completing the final product in the shape and dimensions required by the customer using machining facilities such as CNC, milling, and lathe

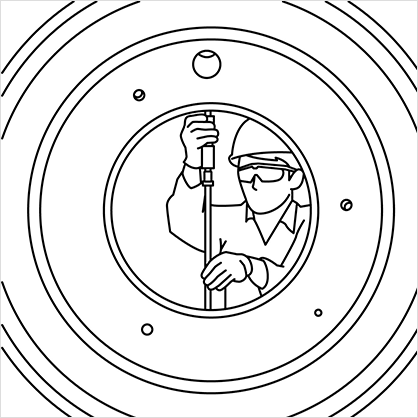

Process of inspecting and selecting the best product that satisfies the quality requested by the customer using various inspection equipment for the finished product

Process of packaging the product and transporting it to a location designated by the customer in order to deliver to the customer in the best condition according to the customer's requirements

-

Raw material

-

Heating

-

Forging

-

Cutting

-

Heat treatment

-

Machining

-

Inspection

-

Packaging & Delivery